Molded PMMA plate Helioplate HD6

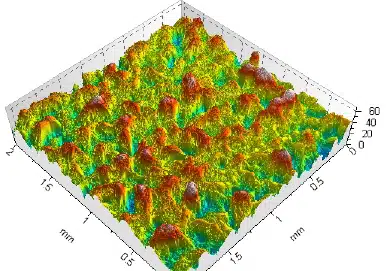

Through our knowledge and expertise, WENEOS has developed the Helioplate HD6, a revolution in the field of substrates for sun protection evaluation, marking the advent of the world’s first patented molded PMMA substrate. Meticulously engineered using an exclusive molding process, the Helioplate HD6 substrate is synonymous with quality and precision, guaranteeing the reproducible roughness essential for reliable in vitro absorbance measurements.

Accompanied by a quality certificate, each Helioplate HD6 substrate ensures compliance with international standards such as ISO 24443 (2012 and 2021), ISO 23675:2024, ISO 23698:2024 and others, making this substrate indispensable for the accurate assessment of Sun Protection Factors(SPF), UVA protection(UVAPF), and more. Designed to be UV-transparent, non-fluorescent, photostable and inert to the various ingredients tested, Helioplate HD6 substrate stands out as the solution of choice for professionals demanding the highest quality in their solar analyses.

Optimized for use with robotic spreading system

SPREADMASTER

robotized spreading system, the Helioplate HD6 substrate facilitates uniform and precise application of suncare products, increasing the reproducibility and reliability of test results. This combination of technical innovation and standards compliance makes Helioplate HD6 the reference molded PMMA substrate for laboratories and research institutes dedicated to the advancement of suncare.

roughness (Ra)

quality certificate

%

compliance with solar standards

Product information

Directions for use

Polymethyl methacrylate (PMMA ) substrate (plate) on which the solar product will be applied for absorbance measurements.

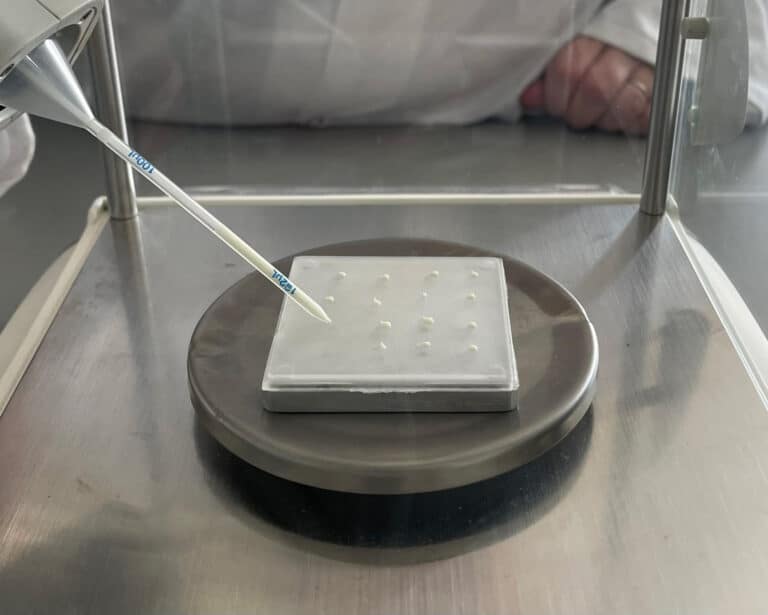

When using this substrate, it should be handled by the edges and moved using a support (metal gondola) to keep the surface temperature as stable as possible.

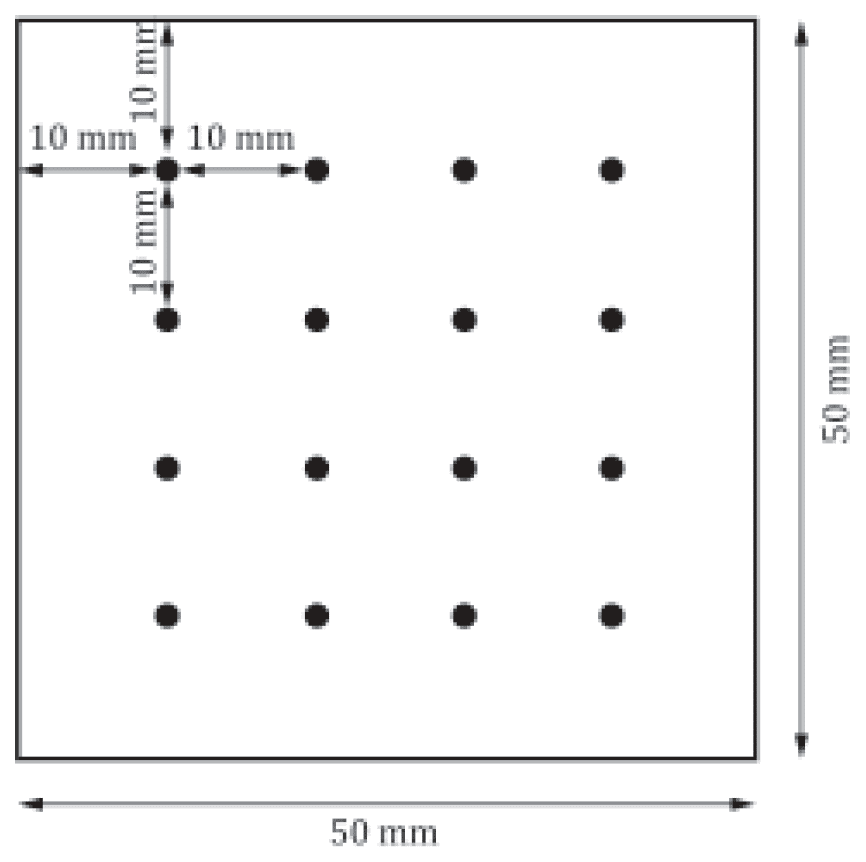

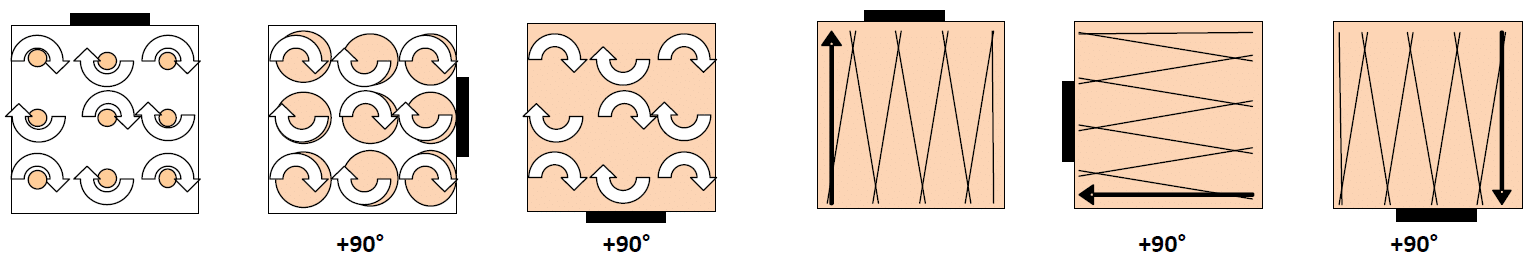

The droplets should be applied evenly (equidistantly) to the rough surface of the PMMA plate, as shown in the diagram below:

The sun protection product is applied to a new untreated rough PMMA sheet with the rough side up (use only once, cannot be cleaned) by mass, at an application rate of 1.3 mg/cm² (±1.6%) according to ISO standards or 0.75 mg/cm² according to FDA 2011.

Given an application area of 47 mm x 47 mm, the quantity applied is 28.7 mg (ISO standard) or 16.5 mg (FDA standard).

The product can be spread manually or robotically, depending on the standard used, using the SPREADMASTER. The product should be spread in a two-phase process with circular and then linear movement cycles, as shown in the diagram below, for example:

For all types of product, the treated sample must be left to dry for a set time in the dark at a controlled temperature (using the THERMASTER) before proceeding to the next steps (spectrophotometric measurement, UV exposure, etc.).

Technical information

| Dimensions | L : 50 mm x W 50 mm x H : 1.5 mm |

| Weight | 4.5 g for one plate |

| Packaging | Bag of 50 plates |

| Compliance |

|

Rough surface (parameters) |

|

Optical property |

|

| Chemical substances |

|

| Conditions of use |

|

| Storage |

|

Environmental features

| Composition |

|

Made in France

Manufactured in an ISO 9001:2015 certified environment

Patented manufacturing

Discover our products compatible for better results

Helioplate SB6

Metallic support

PMMA plate support

THERMASTER

Thermal chamber

SPREADMASTER

Spreading robot