Sunscreen testing is about to become more ethical, economical, reliable (in terms of SPF measurement) and fast, thanks to a recent initiative by the International Organization for Standardization (ISO), a non-governmental organization that develops and publishes international standards. The group has recommended two new test standards for final approval.

The standards, known as ISO 23675 and ISO 23698, represent major advancements in sun protection testing. Their recommendation is a monumental success, after years of development.

The standards are now in the final stages of the draft international standard, scheduled for publication in early 2025.

ISO 23675 (in vitro SPF test)

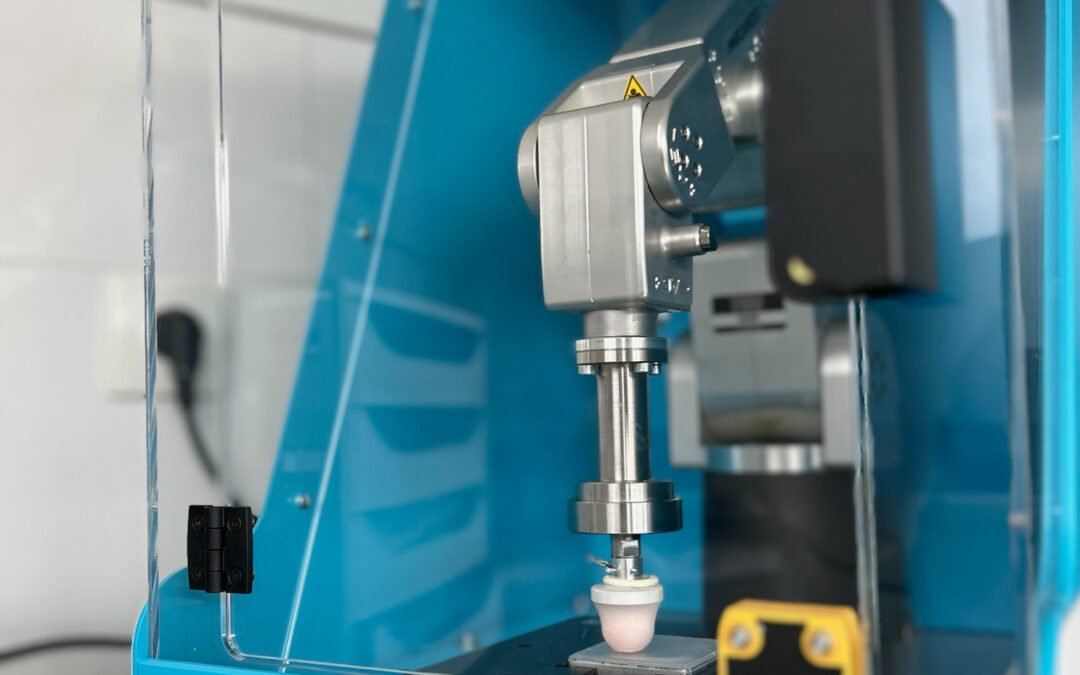

As described by ISO, the “Double Plate” 23675 in vitro SPF test method is based on UVR transmission spectroscopy, where “spectrophotometric measurement of UVR transmission through suitable UVR-transparent substrates” predicts in vivo SPF values.

“This in vitro SPF method showed high reproducibility and correlation with in vivo SPF values,” ISO reported.

The method is applicable to sunscreen products in the form of an emulsion or alcoholic one-phase formulation, excluding loose or compressed powder or stick forms. Specifications are provided to enable the spectral absorbance characteristics of SPF protection to be determined in a reproducible way.

“Use of this method is strictly for the determination of a static sun protection factor,” ISO noted. “It is not validated for the determination of water resistance properties of a sun protection product.”

ISO 23698 (HDRS Sunscreen Testing)

Method 23698, or Hybrid Diffuse Reflectance Spectroscopy (HDRS) method, according to ISO, provides “a non-invasive optical assessment of the protection offered by topically applied sunscreen products, measured in situ on human skin as used by consumers, without requiring physiological responses and without causing physical damage to the test subject.”

According to ISO, “by combining in vitro spectroscopic measurements across the sunscreen spectrum with optical measurements of sunscreen transmission in the UVA on human skin, a hybrid spectrum is obtained that offers a comprehensive assessment of both the magnitude and extent of sun protection in the UVB and UVA regions of the solar spectrum, correlating closely with the in vivo SPF and in vitro FPUVA test results demonstrated during validation of this test method.”

This method describes a procedure for characterizing the sun protection factor (SPF), UVA protection factor (UPF) and critical wavelength (CW) of sunscreen products without requiring biological responses. The method has reportedly been validated for emulsions and single-phase products.

“Specifications are given to enable determination of the absolute spectral absorbance characteristics of a sunscreen product on skin to estimate sunburn and UVA protection,” the standard states. “It is applicable to products that contain any component able to absorb, reflect or scatter ultraviolet (UV) rays and which are intended to be placed in contact with human skin.” This method is presented as an alternative to the ISO 24443 and ISO 24444 methods.

Why ISO’s Approval is Exciting

Sébastien MIKSA, Managing Director of Weneos (formerly Helioscreen), sees the approval of these standards as a major step forward for the industry. “This news is exciting because it represents a major advancement in sun protection testing methods, which will improve the ethical, speed, cost-efficiency and reliability of SPF measurements compared to the in vivo reference method,” he wrote.

“The journey to final approvals took so long due to the complexity of developing methods that are both robust and universally acceptable,” he added. “It required extensive collaboration, innovation and numerous validation tests to ensure the new standards met the high accuracy and reproducibility required by the industry.”

Mr. Sébastien MIKSA’s role in relation to ISO 23675 was to design and develop a robotized spreading technique, and to publish the principle of the in vitro SPF evaluation method via the dual approach, which was validated by Cosmetics Europe and the ISO group.

He also took part in the validation and characterization ringtest and supported its technical aspects.

For ISO 23698, he reports that he mainly challenged the method’s technical limits in order to improve its potential. Beyond these roles, he is also project leader for the ISO 24443 revision..

How it Will Impact Sunscreen Formulators

“The new SPF test methods, ISO 23675 and ISO 23698, will greatly benefit suncare product developers,” continued Mr. Sébastien MIKSA. “These methods offer faster and more cost-effective testing, with improved accuracy and consistency. This will streamline the development process, reduce expenses, and ensure that products provide reliable sun protection. Consequently, developers will be able to innovate more efficiently while maintaining high standards of quality and safety for consumers.”

Next Step Toward Final Approval

As indicated, the methods should be officially published in early 2025.

“When the ISO standards (ISO 23675 and ISO 23698) are published, both methods will be implemented and available for evaluating sun protection,” explained Mr. Sébastien MIKSA. “Acceptance of the results or methods is ultimately determined by regulatory requirements.”

Furthermore, in the European Union, in accordance with the Commission Recommendation of September 22, 2006 on the efficacy of sunscreen products and the claims made on them (2006/647/EC), “these alternative methods will be directly accepted as it is clearly stated that preference should be given to in vitro test methods that provide an equivalent level of UVB protection”.

Mr. Sébastien MIKSA concluded: “The future of sunscreen testing looks extremely promising, and I can’t wait to see these advances become reality.”

Jun 10th, 2024 Rachel Grabenhofer, C&T, with Sébastien Miksa, Weneos (formerly Helioscreen)

Find the Link to the article : here